Difference between revisions of "Textile mechanics"

| Line 1: | Line 1: | ||

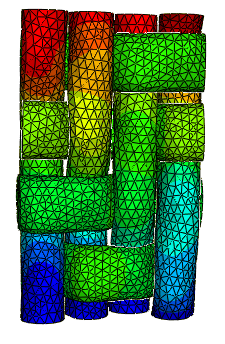

| − | [[Image: | + | [[Image:c5tension.png|thumb|Figure 1a]] |

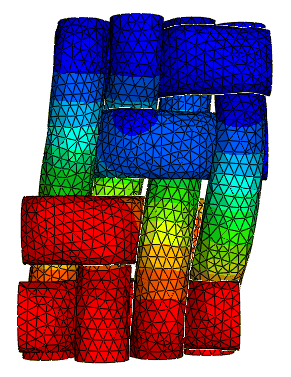

| − | [[Image: | + | [[Image:c5shear.png|thumb|Figure 1b]] |

TexGen has been used to create the geometry of fabrics for meso-scale textile mechanics modelling. Meshing can either be done directly within TexGen or geometry can be exported to the two most common CAD exchange file formats, IGES and STEP. Alternatively Python scripts can be used to transfer geometry to specific third party applications such as ABAQUS. | TexGen has been used to create the geometry of fabrics for meso-scale textile mechanics modelling. Meshing can either be done directly within TexGen or geometry can be exported to the two most common CAD exchange file formats, IGES and STEP. Alternatively Python scripts can be used to transfer geometry to specific third party applications such as ABAQUS. | ||

Revision as of 14:37, 1 November 2011

TexGen has been used to create the geometry of fabrics for meso-scale textile mechanics modelling. Meshing can either be done directly within TexGen or geometry can be exported to the two most common CAD exchange file formats, IGES and STEP. Alternatively Python scripts can be used to transfer geometry to specific third party applications such as ABAQUS.

Mechanical models of commercial fabrics have been created in which textiles were meshed and then exported to the ABAQUS finite element analysis (FEA) package. Deformations were predicted for fabric unit cells in tension, compression, shear and bending, utilising their measured equivalents for individual yarns as input data. Fig 1 shows a modelled deformed twill weave unit cell in tension, compression, shear and bending. Validations of the FE predictions for the mechanical properties against experimental data are shown in Fig 2.