Textile permeability

TexGen has been used to generate models to predict reinforcement permeability using a variety of techniques.

Initial studies utilised commercial computational fluid dynamics (CFD) software to relate fluid velocity to pressure drop for steady-state flow through a textile model[1]. This was generated automatically using a script file from TexGen. Navier-Stokes flow was modelled in the open channels (between tows), and Darcy flow was modelled within the (unidirectional) tows. Whilst this approach is accurate in theory, a number of problems were encountered. The main difficulty was that it was not always possible to generate a conformal CFD mesh using commercial software, particularly when tows were tightly packed (as is usually the case in composites manufacture). Also model build and run times were prohibitive for running parametric and stochastic studies.

Based on the above experience, a number of approaches have been developed to simplify the flow domain[2]. The aim is to capture the essential physics of the process, whilst reducing the number of degrees of freedom and the complexity of the domain to facilitate discretisation. The Grid Average method imposes a square grid of nodes onto the flow domain, and it is at these locations that pressure is determined during flow. Gaps are assigned an equivalent permeability, whilst predictive models (eg. Gebart) are used to predict directional permeability for the UD tows. In 2D Grid Average the flow domain is collapsed onto a 2D grid, with each node assigned a thickness weighted average permeability. This results in very fast computation times (consistently less than 30 sec) compared to 3D Grid Average and CFD approaches.

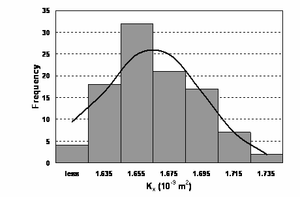

The 2D Grid Average approach was compared to commercial CFD for a fairly open textile structure, providing predicted permeabilities typically within 30% of each other[3]. 2D Grid Average was then used to assess effects of fabric architecture - particularly intra-ply shear (from draping) and variability in tow path on permeability[4]. The latter allowed predicted permeability distributions to be produced using a stochastic (Monte Carlo) approach. Such data allows variability in flow to be simulated, which in turn facilitates development of flow process control strategies[5].

Recent collaborative work with K U Leuven has compared results from 2D Grid Average with their voxel based Navier-Stokes solver, showing close similarities between predicted trends from parametric studies with the two codes[6]. The next phase of work will involve prediction of permeability for 3D woven textiles, and also modelling of transient flow to predict void entrapment.

References

- ↑ F. Robitaille, C.C. Wong, A.C. Long, C.D. Rudd. “Systematic predictive permeability modeling using commercial CFD and dedicated calculation method”, Proc. 14th Int. Conf. on Composite Materials (ICCM-14), San Diego, July 2003.

- ↑ C.C. Wong. “Permeability prediction for multi-layer textile preforms”, PhD Thesis, University of Nottingham, 2006.

- ↑ C.C. Wong, A.C. Long, M. Sherburn, F. Robitaille, P. Harrison, C.D. Rudd. “Comparisons of novel and efficient approaches for permeability prediction based on the fabric architecture”, Composites Part A 37(6) 2006 847-857.

- ↑ C.C. Wong, A.C. Long. “Modelling variations of textile fabric permeability at mesoscopic scale”, Plastics Rubber and Composites, 35(3) 2006 101-111

- ↑ D.K. Modi, N.C. Correia, M.S. Johnson, A.C. Long, C.D. Rudd, F. Robitaille. “Active control of the vacuum infusion process”, In press (available on-line), Composites Part A 2007.

- ↑ B. Verleye, S. Lomov, A.C. Long, D. Roose, C.C. Wong. "Permeability of textile reinforements: efficient prediction and validation", Proc. 16th Int. Conf. on Composite Materials (ICCM-16), Kyoto, July 2007.